GeoScan’s partner company Xradar are regularly called to scan sites previously scanned by other companies in order to verify the work, or to correct failed scans

The issue with GPR (Ground Penetrating Radar) is that it is currently an unregulated industry and many companies operate with untrained technicians. This can cause major problems for those utilizing these services and can generate a lack of trust in the technology.

At GeoScan we have developed Xradar, an advanced imaging capability, utilizing GPR technology. Xradar uses radar amplitude, phase and shape to achieve maximum performance for freehand B-scan analysis.

Xradar has the ability to accurately locate objects beneath the surface that GPR cannot. In addition, all of our technicians are fully trained experts and can guarantee the results of our scans.

Verifying a Core Location

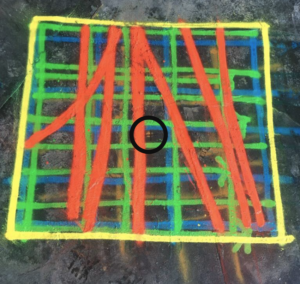

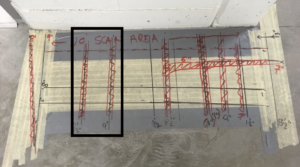

We were recently called to a site where an engineer would not clear a hole for coring in an area that had been scanned by another company. Our trained technician performed a scan using Xradar and proved the engineer’s concerns were justified. In the below images you can see the clear difference in the detection capabilities of GPR vs Xradar.

The proposed core location is indicated by the black circle. While Figure 1 appears to have detected the top rebar for the most part, it cannot see past the “shadowing” created by this layer. In Figure 2 you can see that Xradar is able to see past this shadowing and allowed our technician to mark out Top Rebar (Green), Electrical Conduits (Red), and Bottom Rebar (Blue).

Had this core gone ahead originally it would have cut through an electrical conduit resulting in costly damage and more project time to correct the error.

Fast and Accurate Scanning

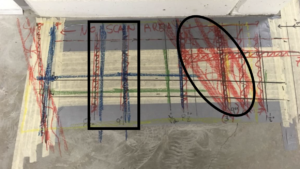

The process of scanning concrete with Xradar is incredible efficient and flexible. When scanning an area to core a hole you can know within a few moments whether the location will work, or a new one needs to be considered. A recent example of this can be seen in the below images where GeoScan were called for a second opinion following a GPR scan from another company. In Figure 3 the company were confident they had mapped out the top layer of steel and advised the client that they could not see anything below this layer of steel.

An Xradar technician performed a scan and within just 15 minutes identified and mapped out the contents of the slab. As you can see in Figure 4 the original scan was very far off and even missed an Electrical Conduit (Red).